Services

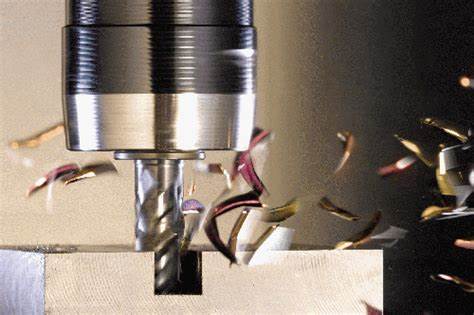

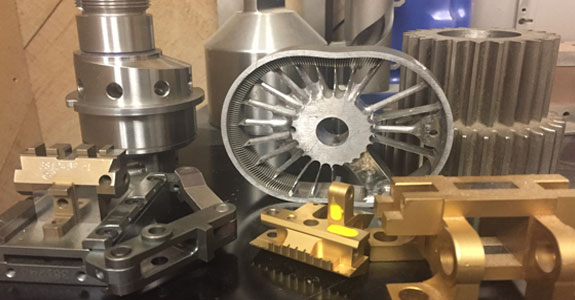

Because of Century Tool Company’s commitment to providing the highest standard of service and quality to its customers, it has gained the recognition as one of the top precision tool shops in the industry.

Century Tool Company proudly offers the following machinery for your manufacturing needs.

| 1 | Doosan | 2023, DNM 4500 Vertical Machining Center. 40x24x24 capacity |

| 1 | Doosan | 2024, SVM 4100, 4 axis Vertical Machining Center. 30x16x24 capacity |

| 1 | Hurco | 2018, VM1 Vertical Machining Center. 16x14x24 capacity |

| 1 | Hurco | 2024, VM1 Vertical Machining Center. 16x14x24 capacity |

| 2 | Feeler | 2015, High speed VMC 20x16x26 capacity |

| 1 | Quaser | 2013, High speed VMC 42x24x24 capacity |

| 1 | Southwestern Industries | 2021, TMC 7 Vertical Machining Center. 30x20x20 capacity |

| 2 | Prototrak | 2010, SM, 3 axis, CNC controlled Bridgeport |

| 2 | Prototrak | 2010, SM, CNC controlled Bridgeport |

| 6 | Prototrak | 2000, MX2E, CNC controlled Bridgeports |

| 6 | Prototrak | 2000, A.G.E. 2 CNC controlled Bridgeports |

| 1 | Prototrak | 2005, MX3, 3 axis CNC controlled Bridgeport |

| 2 | Southwest Industries | 2020, TRAK/DPM 5 with RMX control |

| 1 | Southwest Industries | 2019, TRAK/DPM 2 with SMX Control |

| 1 | Fanuc | 2000 Robocut Alpha OC, automatic wire fed, 4 axis Wire EDM 6 x 9 x 13 |

| 1 | Fanuc | 2022 Robocut C-400ia, automatic wire fed, 4 axis Wire EDM 6 x 9 x 13 |

| 1 | Fanuc | 2021 Robcout C-600ia, automatic wire fed, 4 axis wire EDM, 10 x 13 x 18 |

| 1 | Fanuc | 2013 Robocut Alpha 0E automatic wire fed, 4 axis wire EDM 10 x 13 x 18 (2012) |

| All machines are equipped with Herman Schmidt tooling. | ||

| 1 | Eltee | Sinker Edm |

Surface |

||

| 7 | Harig | 2000, Super 612 wet grinders with 6 x 12 inch chucks |

| 2 | Jones & Shipman | 1990, Model 540 wet grinders with 6 x 18 inch tables |

| 1 | Okamoto | 2010,3 axis autofeed wet grinder with 6 x 18 table |

| 1 | Okamoto | 2010, ACC-12-24DX Autofeed wet grinder with 12 x 24 table |

Cylindrical |

||

| 1 | Jones & Shipman | Model 1300 ID/OD grinder with 13 x 27 inch capacity |

| 1 | Myford | OD grinder with 3 x 9 inch capacity |

| 1 | Newbould | 2015, Indexer 1/5 hp variable speed motor, T.I.R. less than .00005 |

| Each grinder is supplied with toolroom grade surface plates that are relapped every two years | ||

| 1 | Bridgeport | 2002, EZ Path CNC Lathe Capacity 17" swing x 40" Travel |

| 1 | Yama-Seiki | 2017, 30HP 12 station turning center |

| 2 | Leblond | Regal 15 x 60 inch capacity with digital readouts |

| 2 | Hardinge | Super Precision tool room lathes with ACCU-RITE III digital readouts |

| 1 | Haas | 2012, CNC 4th axis rotary head. |

| 1 | Moore | 1980, #2 Jig Grinder with Sony .00002 Digital Readout |

| 1 | Moore | 1985, #3 Jig Grinder with Sony .00002 Digital Readout |

| Fanuc | PC FAPT Cut Cad-Cam System, 2024- DXF Format |

|

| Autodesk | Feature Cam Version 2025 (upgraded yearly) | |

Fusion 2025 |

| Starret | 18 inch Master Height Gage | |

| Brown & Sharpe | Microval 454 manual CMM with PC monitor and printer w/ Reflex Software | |

| Micro Vu | Digital, power fed optical comparator | |

| Fowler | 24 inch electronic height gage | |

| (4)Fowler Hi Cal | 12 inch electronic height gage | |

| 3 | Mititoyo | 12 inch Height master height gage |

| Deltronic | Inspection pins, .0025mm graduations, inch and metric, (replaced annually) | |

| Fowler | Master inspection blocks (replaced annually) | |

| Meyer | Master inspection plus minus pins from .01-1.00 | |

| Starret & Mititoyo | Dial bore and IntraMics ranging from 3mm to 5 inches | |

| 2 | Starret | 18 inch by 24 inch pink toolroom grade surface plate (relapped every two years) |

| Doall | 24 inch by 30 inch inspection grade surface plate (relapped every two years) | |

| Wilson | Hardness tester, Model 3JRU | |

| Mahr Federal | Digital RA surface gage. | |

| Technical Consultants | Gillette certified GD&T inspectors |